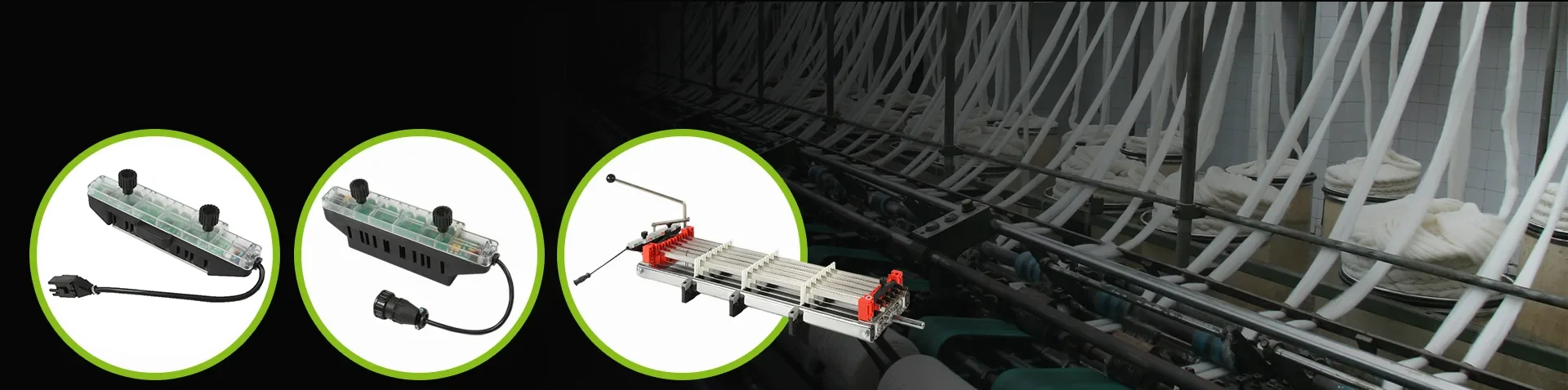

This Quality warp stop monitor for looms, a leading product of Changshu Changxin Textile Equipment Co., Ltd., is an electronic single-column display module designed specifically for warp stop frames on air-jet looms. It monitors warp breakage in real time and provides feedback through a single-column display. It is precisely adapted for various air-jet looms, including those from Toyota and other countries. Its active monitoring function improves warp breakage response efficiency, providing intelligent electrical support for stable air-jet loom production. It is an ideal choice for textile companies seeking controllable weaving processes.

The core advantage of this Durable warp stop monitor for looms is its combination of real-time monitoring and precise display. Utilizing high-precision sensors and an electronic single-column display module, warp-break detection response times are kept within seconds, even at high speeds on air-jet looms, with display positioning accuracy reaching the level of a single spindle.

The internal circuitry has been optimized for interference resistance, significantly improving signal transmission stability and minimizing false alarms in the high-frequency vibration and airflow interference environments of air-jet looms. The structural design conforms to the installation standards for warp-stop frames on air-jet looms, making it highly compatible with mainstream air-jet looms like Toyota. It can be directly connected to the warp-stop frame system during installation, eliminating the need for additional loom modifications.

The housing is constructed of flame-retardant insulating material, effectively protecting against fiber dust and moisture erosion during air-jet loom operation. The operating temperature range extends from -10°C to 60°C, ensuring stable operation in complex workshop environments and a mean time between failures of over 9,000 hours.

The High-Efficiency warp stop monitor for looms features outstanding features: an electronic single-column display provides real-time feedback on the warp break location, making monitoring more intuitive. Its active monitoring function changes the traditional passive warp break management model, adapting to the high-speed production pace of air-jet looms.

It is widely compatible with various air-jet looms, including Toyota's, both domestically and internationally. It is particularly suitable for large-scale air-jet loom production lines with high weaving efficiency requirements. Through precise monitoring, it can reduce fabric defects caused by warp breaks and improve product quality consistency.